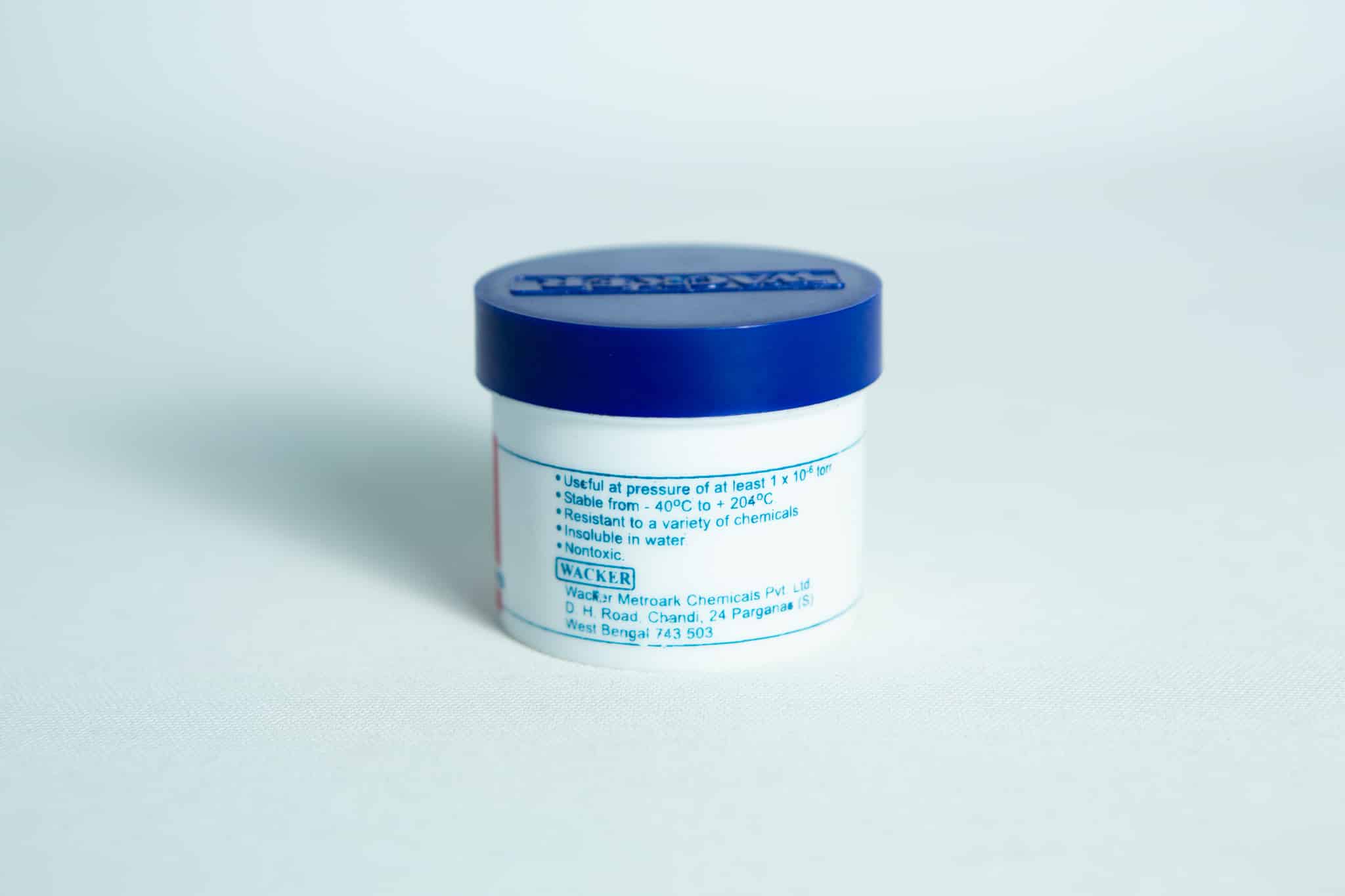

Description

Metroark 211 Compound is a stiff, non-grease-like silicone material. It maintains its consistency over a wide temperature range of—400 °C to 2500 °C. Its low volatility, very low vapour pressure of the base, chemical resistance, relatively constant consistency over a wide temperature range, and sealing ability make it an ideal sealant for high vacuum and high pressure systems and sealant-cum-lubricant for chemical processing equipment.

Net Weight: 50gms

Lubricating the Metal-to-Metal Seal on an All-American Steriliser (for Mycology Use)

All American sterilisers feature a unique metal-to-metal seal, which means they do not use a rubber gasket. To maintain a proper seal and prevent sticking or damage during use, it’s essential to lubricate the contact surfaces where the lid meets the steriliser’s body.

Why Lubrication is Important

Prevents galling or seizing of the metal surfaces.

Ensures a tight and even seal during pressure cycles.

Makes opening and closing the lid easier and safer.

Instructions:

Apply a small amount to a clean paper towel or lint-free cloth.

Rub the lubricant along the top rim of the steriliser body (where it meets the lid). Also, apply a thin layer to the corresponding inner lip of the lid.

Ensure the lubricant is spread evenly without clumps. A thin, even film is ideal, not excess.

Use a clean paper towel to remove any visible excess, leaving just a light film.

How Often to Lubricate:

Every 3–5 uses or when you notice increased resistance when sealing/unsealing.

Clean old residue occasionally with isopropyl alcohol before reapplying fresh lubricant.